Ford Uses Two Different AI Systems for Quality Control in Its Factories

⬤ Ford deployed two AI systems—AiTriz and MAIVS—to detect assembly defects in real time.

⬤ These tools aim to reduce costly recalls, with Ford already issuing a record 94 recalls in 2025.

⬤ AiTriz uses live video for precision; MAIVS relies on smartphone images across 700+ stations.

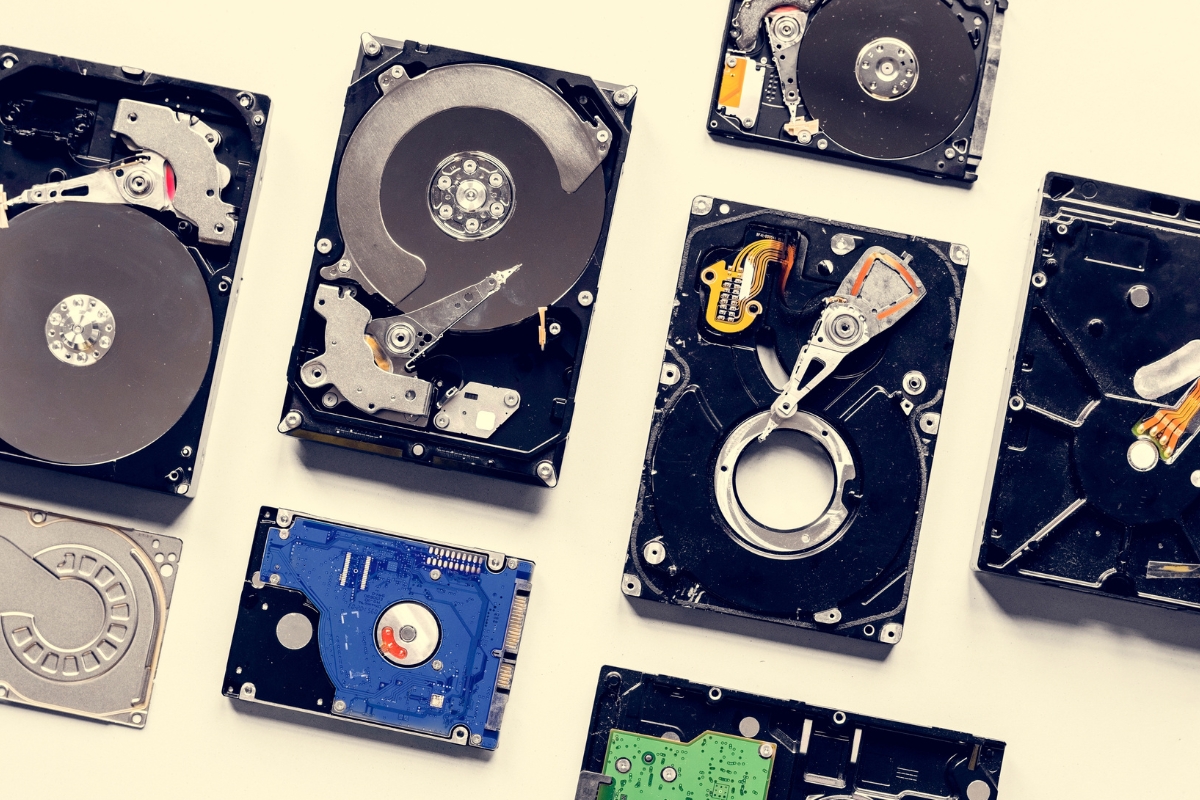

Ford has introduced two new AI-powered systems designed to help factory workers detect small issues in vehicle components during the assembly process. The systems check whether the correct interior trims have been installed in each vehicle and verify that every electrical connection has been properly fitted.

More than 300,000 F-150 trucks are produced every year at Ford’s Dearborn Truck Plant. The model is known for its wide variety of configurations and components, including trim levels, electrical parts, wiring harnesses, logos, body panels, and seat designs.

To improve production and quality control, Ford has deployed two internally developed systems called AiTriz and MAIVS, both capable of detecting defects in real time. AiTriz, implemented in December 2024 and named after its developer in Spain, Beatriz García Colado, uses machine learning and live video streams to spot deviations down to the millimeter. MAIVS, launched earlier in January 2024, relies on still images captured by smartphones mounted on 3D-printed stands to verify that all correct parts are installed on each vehicle.

The two systems work together to help workers identify problems immediately before they escalate into costly warranty claims, recalls, or rework, which is an area Ford has been striving to improve after leading the auto industry in recall numbers for four of the past five years.

These tools could play a major role in addressing the company’s ongoing recall challenges. So far this year alone, Ford has issued a record 94 recalls, most of them affecting vehicles produced before 2023; the highest number of safety bulletins recorded by any major car brand in a single year.

Patrick Fry, Engineering Manager at the Dearborn plant, said the systems have already improved operations by allowing early detection of issues rather than waiting until the final inspection phase. “That speed matters,” he explained. “Before systems like AiTriz, many electrical problems wouldn’t show up until the final inspection, and fixing them later often meant removing seats or floor mats.”

Ford’s new systems are now installed across dozens of stations in North America, with AiTriz operating in 35 stations and MAIVS in about 700. While MAIVS relies on still imagery, AiTriz offers greater precision and flexibility through live video feeds, especially in cases where visual obstructions occur, such as a worker walking past the camera or metallic parts blocking the view.

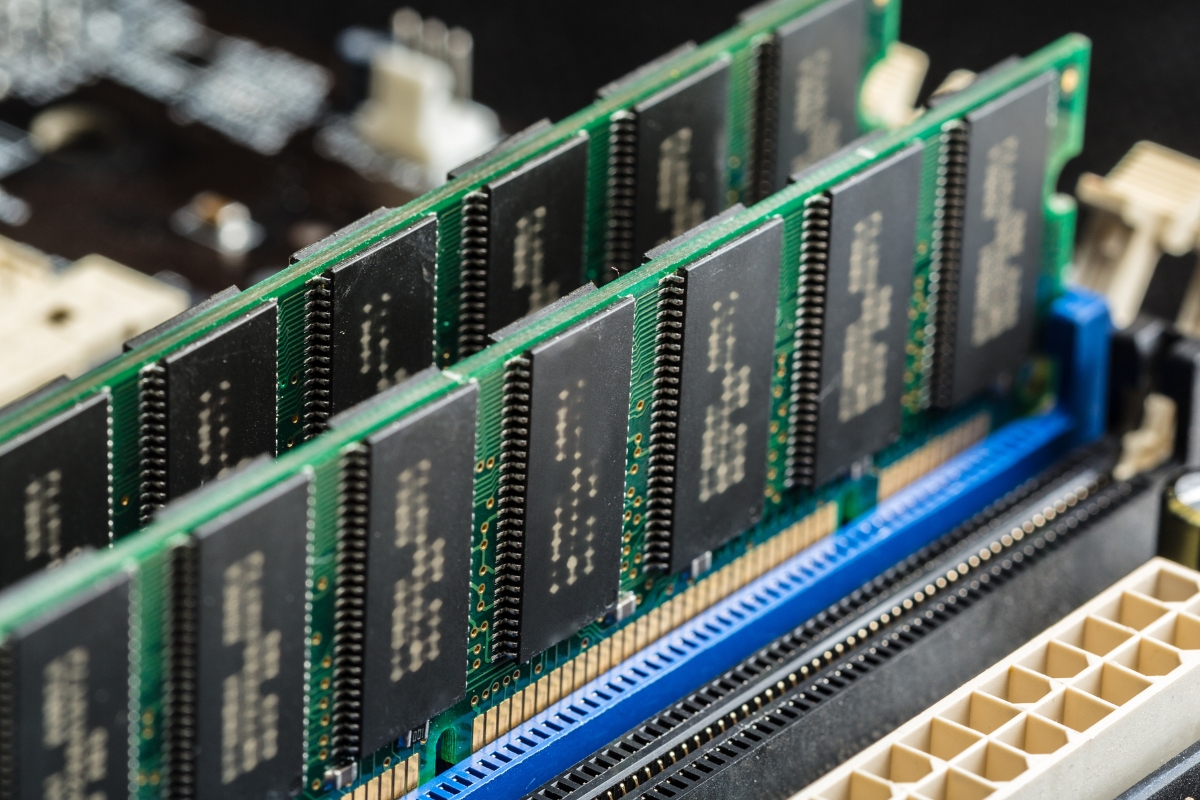

Analysts see strong long-term potential for these systems to reduce recalls, though the technology is still in its early stages. Ford executives emphasize that the goal is not to replace workers but to support them, as vehicle models become increasingly complex and rely more on advanced sensors, chips, and processors.