CEO of ARM: Robots are coming for factory jobs within a decade

Physical AI could represent the technology industry’s next major bet, according to Arm CEO Rene Haas, who believes advanced, AI-powered robots will soon replace large segments of the human workforce, particularly in manufacturing.

Speaking at a recent event in San Francisco, Haas outlined a future shaped by agentic AI and robotics, predicting that humanoid robots will take over most factory jobs within the next five to ten years. This is especially noteworthy as manufacturing is estimated to employ over half a billion people worldwide.

Haas argued that a key driver of this shift is flexibility. Unlike today’s industrial robots, which are typically designed for a single, narrowly defined task, future “physical AI” robots could be reprogrammed and adapted to perform a wide range of jobs. Haas emphasized that the ability to switch tasks quickly makes physical AI far more disruptive than traditional automation.

Physical AI refers to advanced AI systems embedded in robots and other physical machines that enable them to perceive, understand, and interact with the real world. In practice, this means machines that can operate outside controlled digital settings and handle complex, real-world tasks.

Automation is already deeply embedded in manufacturing, but Haas noted that existing robotics remain limited. Current systems rely on specialized hardware and software optimized for specific workloads, which restricts their adaptability. Physical AI, he suggested, could overcome these constraints by allowing humanoid robots to “learn” tasks dynamically rather than being rigidly programmed in advance. This would enable factories to deploy general-purpose robots capable of filling multiple roles, reducing the need for significant human workforces alongside single-function machines.

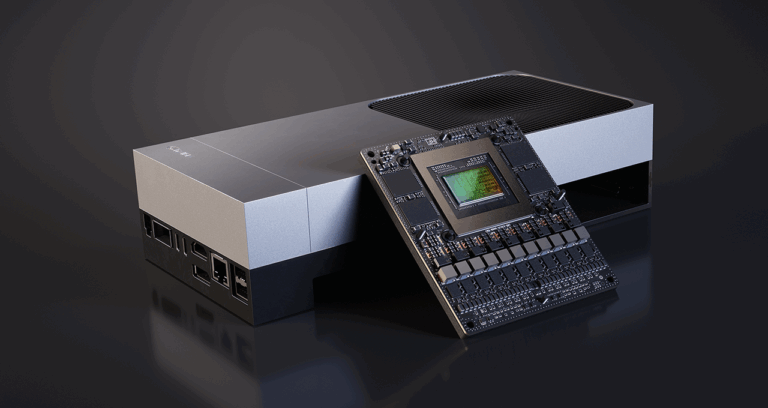

Haas also highlighted autonomous transportation as an example of the trajectory of physical AI. Today’s self-driving taxis, such as those operated by Waymo, depend on extensive hardware setups, including lidar, radar, and multiple cameras. Over time, Haas expects more capable AI models to reduce this hardware burden, handling complex decision-making with fewer sensory inputs.

ARM’s position in the semiconductor ecosystem underpins this vision. Haas noted that the average person already relies on 50 to 100 ARM-based chips across phones, appliances, and other devices. He believes the same efficiency and scalability could soon enable humanoid robots to perform meaningful factory work.