Porsche starts manufacturing its first electric Cayenne

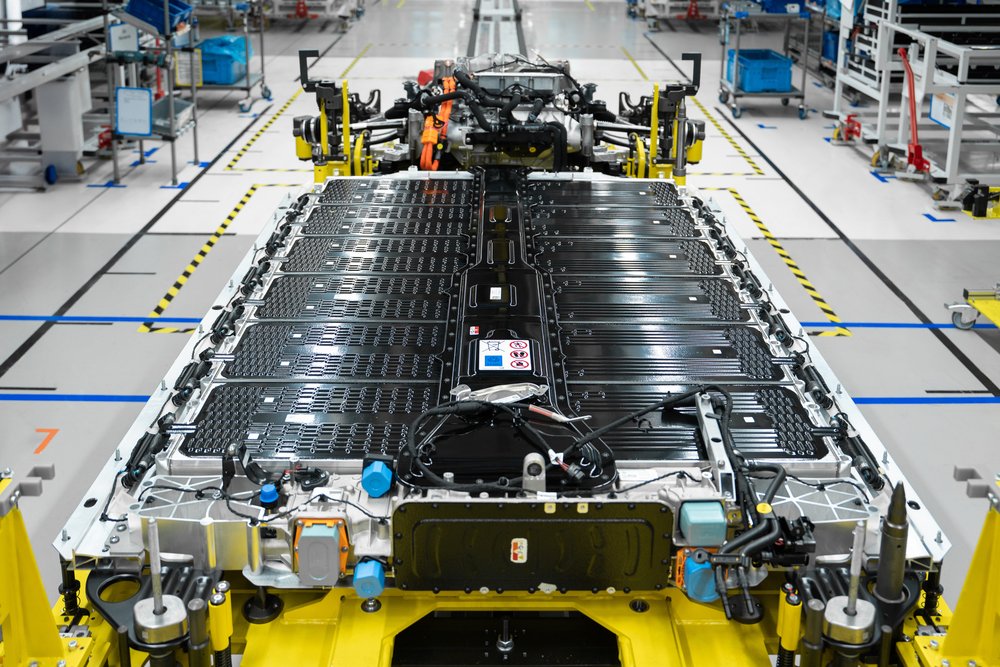

Last November, the Porsche Cayenne Electric celebrated its world premiere, and now Porsche confirms that series production is already underway in Bratislava. MENA TECH attended the announcement and a subsequent keynote, then participated in a press tour of the company’s manufacturing facilities in Bratislava, Slovakia, gaining insight into its advanced production technologies. In the announcement, Porsche confirmed that the all-electric model is produced on the same line as combustion-engine and hybrid Cayenne models, enabling Porsche to respond quickly to shifts in demand through a flexible manufacturing setup.

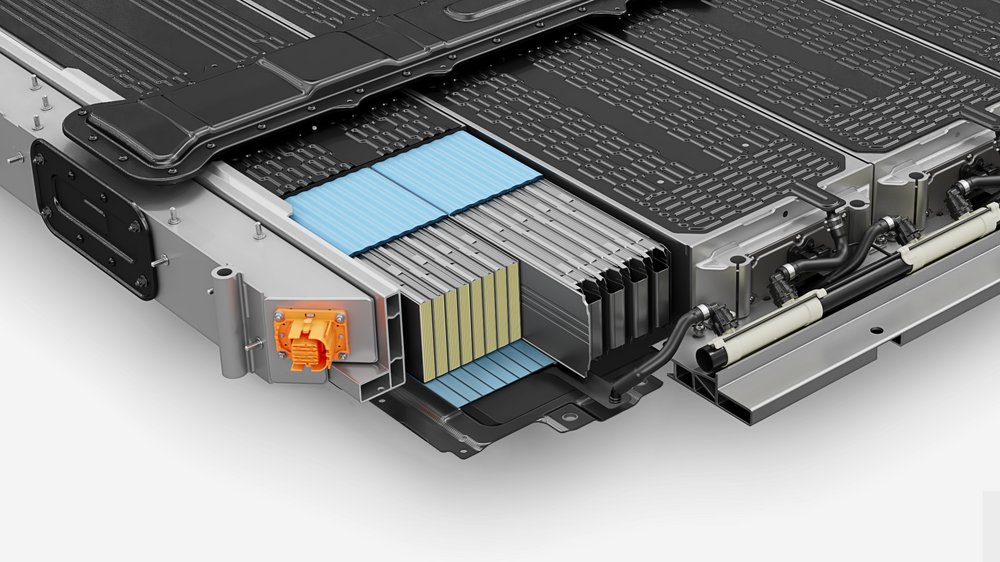

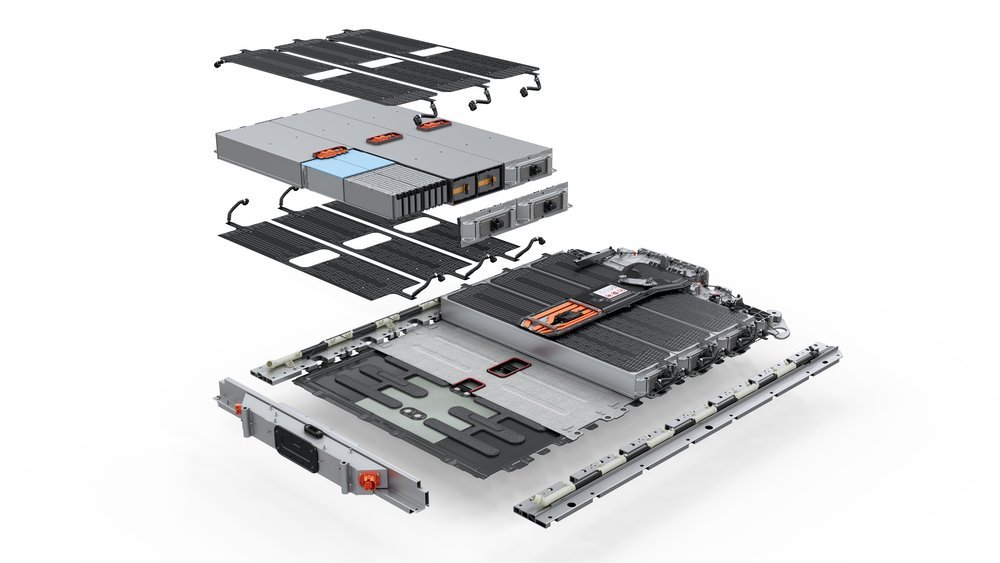

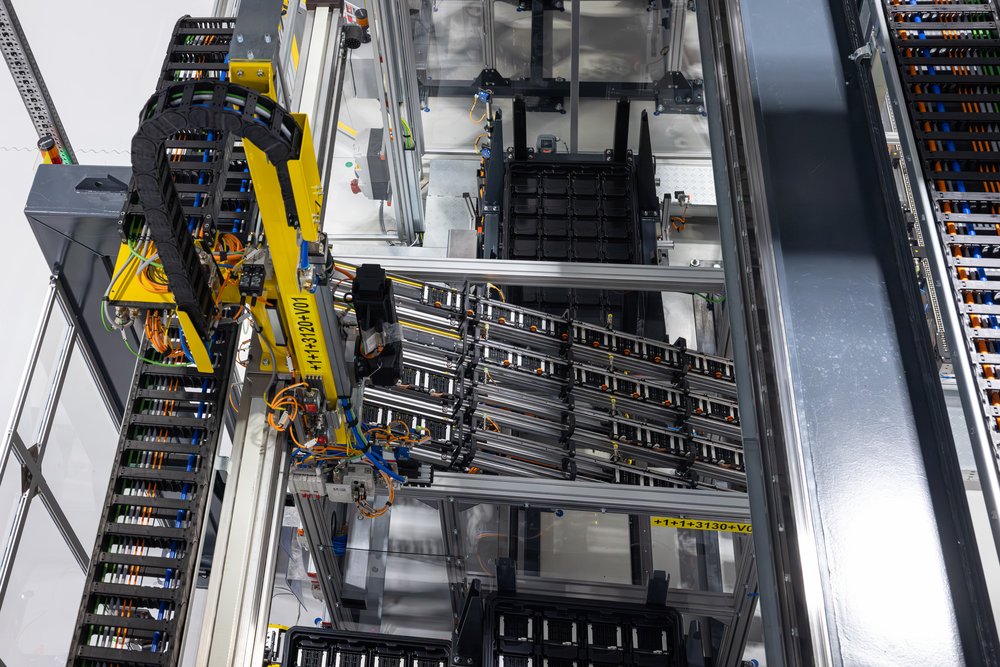

To expand its battery expertise, Porsche is relying on battery modules developed entirely in-house for the Cayenne Electric. These modules are manufactured at the Porsche Smart Battery Shop northeast of Bratislava. According to the company, this approach ensures maximum performance, efficiency, and quality under a “Made in Europe” strategy.

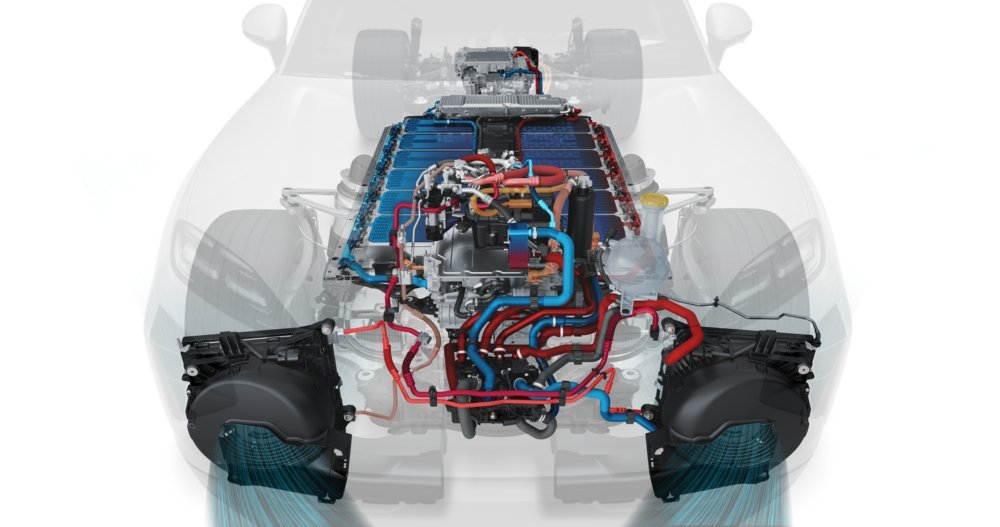

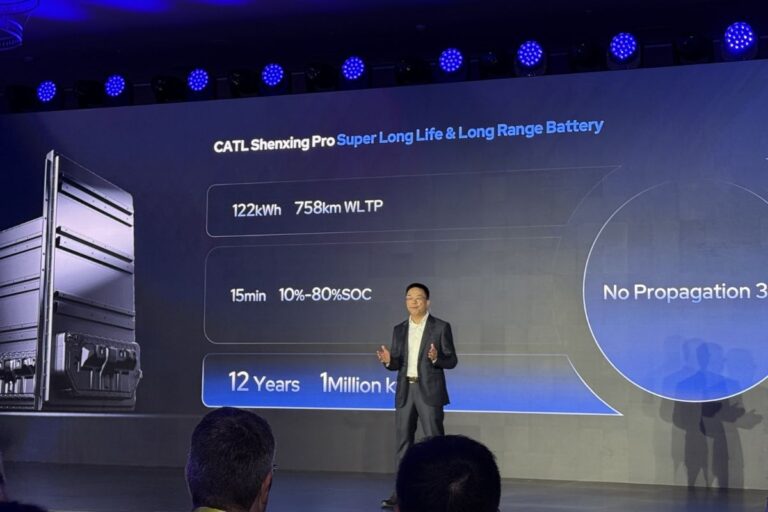

The new high-voltage battery has a gross energy content of 113 kWh and enables ranges of more than 600 kilometres. It supports ultra-fast charging with outputs of up to 400 kW and operates on an 800-volt architecture. A dual-sided cooling system cools or heats the battery from above and below, enabling it to reach its optimal temperature window more effectively.

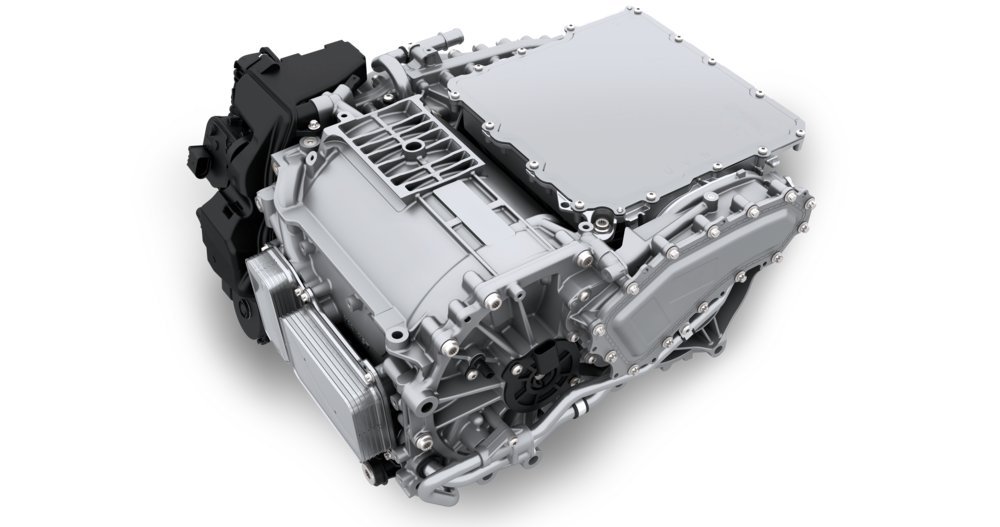

Porsche said the Cayenne Electric is available in three powertrain variants, while all Cayenne derivatives are manufactured on a single production line. In its most powerful configuration, the Cayenne Turbo delivers up to 850 kW (1,156 hp), making it the most powerful Porsche production model to date. The new generation also features the largest screen area ever used in a Porsche, a high response speed for the Porsche Communication Management system, and extensive customization options.

“Through the Cayenne Electric, we are firmly transferring Porsche’s DNA into the future,” said Albrecht Reimold, Member of the Executive Board for Production and Logistics at Porsche AG. He added that in-house battery modules, high manufacturing quality, and a production line combining multiple powertrain concepts provide the flexibility needed to meet market-specific customer requirements worldwide.

Battery production takes place at the Porsche Smart Battery Shop in Horná Streda. The site covers the full production process, including cell preparation, stacking, laser welding, foaming, cold plate integration, and end-of-line testing under full quality control.

“With the Smart Battery Shop, we are bundling decades of industrialisation experience with state-of-the-art battery technology,” said Markus Kreutel, Chairman of the Executive Board of Porsche Werkzeugbau GmbH, adding that this vertical integration gives Porsche control over quality, precision, and scalability.

For Cayenne Electric production, the Volkswagen Group’s multi-brand plant in Bratislava has been extensively expanded, including the construction of a new platform hall. Porsche also maintains a permanent on-site team at the facility to ensure rapid coordination and quality assurance during the production ramp-up.